Dehumidifiers & dehumidification for power plants & steam turbines

The demand for generated power is constantly variable, resulting in plants being brought online at peak demand, typically in winter, and long periods of downtime during the summer months. Whilst there are a number of different technologies used, gas turbine, micro gas turbines, steam turbines are still the largest source of generated power globally and has been for the last 140 years.

There are different types of turbine, condensing, non-condensing, reheat and extracting, but the underlying basic principle of operation is common. Steam turbines operate on the Rankine cycle. In this thermodynamic cycle, water is pumped to high pressure and then heated to generate high pressure steam. The high pressure steam is then expanded through a steam turbine where steam energy is converted to mechanical power that drives an electrical generator.

Steam at pressure is often referred to as dry steam. Extra energy in the form of sensible heat is added at the superheater. This keeps the steam from condensing in the piping or in the turbine nozzles. This ensures that only steam, as a gas, reaches the turbines. This prevents condensed water droplets impinging on the turbine blades. However when a turbine is shutdown and pressure reduces there is a high risk of condensate forming. Liquid water can lead to corrosion on the blades of the turbine, as well as the casing if not removed.

When power plants are taken offline for maintenance or because of excess generator capacity, removal of condensate is an important aspect to be considered. Dehumidifiers can be installed to blow dry air through both the steam side and generator windings. This costs less and is safer than purging with nitrogen, and is far more effective than either wet layup with corrosion inhibitors or preservation in grease. “Dry air layup” is very simple, and the plant can go back on-line in a matter of hours rather than weeks.

-

Desiccant (adsorption) dehumidifier systems offer the best solution. They can be comparatively small and portable. They offer a wider range of operational temperatures typically -30 to +40 °C together with inlet ambient humidity from 0-100%RH. Operationally they can provide humidity levels below 10%RH.

Dry air discharge temperatures can be in the order of 35 to 45°C, which assists in moisture removal. The great flexibility of desiccant dehumidifiers make them ideal for unheated environments.

Benefits of Condair dehumidification in power plants include:

- Prevents corrosion on turbine blades during downtime

- More efficient than wet layup or using corrosion inhibitors

- Comprehensive range of dehumidification technologies

- Free expert advice and dehumidifier system design support

- Local engineering support for reliable operation in critical environments

Condair DA desiccant dehumidifier

Get free expert advice on dehumidifiers for power plants & steam turbines

PODCAST: HOW TO SIZE & SELECT A DEHUMLearn the important things to consider when approaching a commercial dehumidifier project.

Free 10-point guide to specifying dehumidifiers

Download your free 10-point guide to specifying dehumidifiers and get an easy-to-follow overview for planning dehumidifier projects.

It covers system design, dehumidifier selection & sizing, drying psychrometrics, energy saving and much more.

You may also be interested in...

Dehumidifiers for military storage

Vertical farms humidity control

Wind turbine dehumidification

Archives & storage

Hammam, Caldarium and Rhassoul

Steam baths

Outdoor mist cooling systems

Dehumidifiers for ice prevention in cold store and freezers

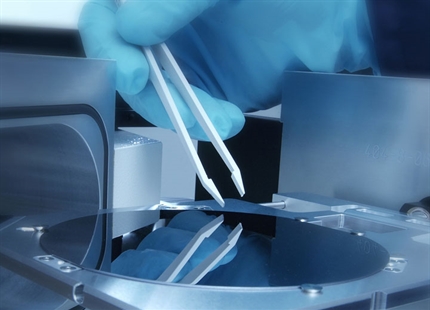

Humidification & humidity control in semiconductor & PCB manufacturing