Humidification & humidity control in paper & pulp production

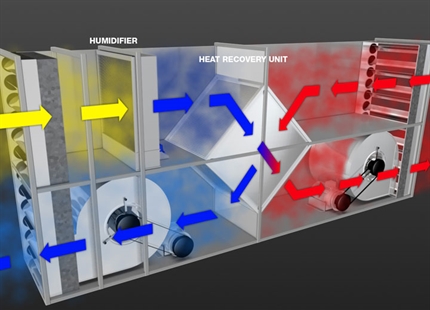

Humidity control in the paper industry is essential to control the moisture loss of the paper after drying. Once produced and reeled, the paper can be exposed to ambient conditions at the end of the paper machine for considerable periods of time. Exposed surfaces of the paper will change in moisture content dependent on the ambient humidity, leading to problems during the slitting and wrapping processes.

Low humidity, below 50%, causes the paper to shrink, curl and lose dimensional stability making the reel of paper unusable and in turn very costly to the manufacturer. To stop this from occurring, the typical humidity level required is 55%rH. When this level is maintained the moisture in the paper maintains not only the flexibility of the product but also its stability during production and packing.

Low humidity in the slitting area will cause moisture losses to occur; these losses will take place very quickly. However, damage to the paper may not be seen at this stage as the tension on the paper prevents any curl or dimensional change being seen.

Changes to the paper in the slitting process will show at the sheeting stage because the tension has been taken off the paper and it is now free to change its shape.

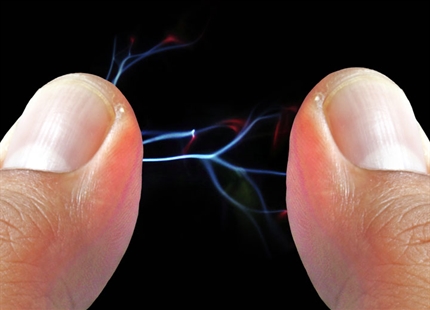

When humidity is below 45%RH static electricity will be generated, which can cause packing issues and prevent a risk to staff from unexpected shocks.

Benefits of Condair humidification in the paper & pulp industry include:

- Extensive expertise around the world with many paper & pulp applications

- Better quality product, increased production efficiency and reduced wastage

- Comprehensive product range to precisely meet customers' requirements

- Low energy systems to reduce operating costs and improve humidity control

- Low maintenance solutions to reduce on-going service requirements

- Comprehensive service of expert advice, design, supply, installation, commissioning, maintenance and spares supply

- Arjowiggins, France

- Ceisa Packaging, France

- Portucel Soporcel, Portugal

- Fabrica Nacional de Moneda Y Timbre

- Rizla, UK

- Duni Paper Mills AB, Sweden

- Holmen Paper Mills AB, Sweden

- Modo Holmen Paper AB, Sweden

- Metsa Tissue as, Slovakia

Use our online product selector

Get free expert advice on humidity control in paper production

PODCAST: HOW TO SELECT & SIZE A HUMIDIFIERLearn how to plan a humidification project.

You may also be interested in...

Mushroom growing humidification

Humidification & humidity control in semiconductor & PCB manufacturing

Steam baths

In-duct evaporative cooling strategies

Hammam, Caldarium and Rhassoul

Eliminating static with humidification

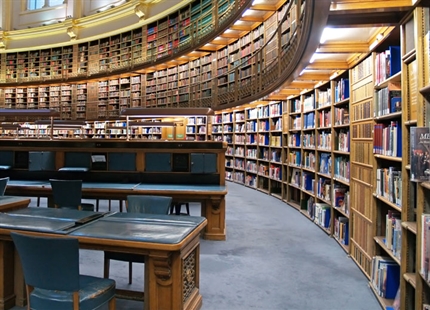

Archives & storage

Office humidification

Dehumidifiers for military storage