Author: Dave Marshall-George, UK & IE Sales Director, Condair Limited

Fighting static with humidity

Static shocks can be annoying in our day-to-day lives, but the build-up of static and the effects it has in manufacturing can mean the difference between a profitable business and a loss-making enterprise. Where people are operating dangerous machinery or for those with medical conditions, a sudden bolt of electricity can also present a very serious safety risk. A surprisingly effective remedy for this issue lies in the moisture content of the air surrounding us.

Static electricity happens when two surfaces come together and then separate. An exchange of electrons across the two surfaces leads to an imbalance in charge, resulting in electrical build-up. If this charge cannot get to ground, it remains in the object. Hence the term “static electricity”, literally meaning lacking in movement.

As we all know, water is an excellent conductor of electricity. This is just as true for water in its gaseous state as its liquid state. If there is enough moisture in the air, electrical charge that naturally occurs in objects can dissipate through it, without any excessive build-up and the resulting issues it causes. This is evident in the fact that issues with static and ESD (electrostatic discharge) mainly occur in the winter, when the indoor environment is much drier.

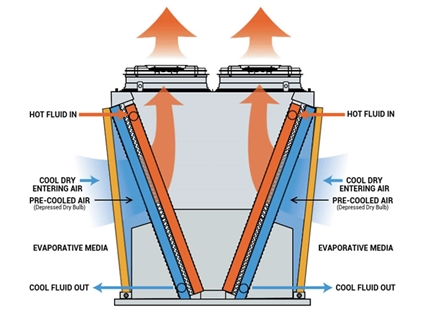

The air outside our buildings directly impacts the quality of the air inside our buildings. In the winter, when the outside air is very cold, it can hold very little water. Its relative humidity is high but its absolute moisture content is low. When this air is brought inside, through mechanical or natural ventilation, and is heated, its capacity of hold water is increased, so its relative humidity drops. When indoor air is below 40%RH, static build-up is much more common.

An indoor humidity of less than 40%RH is quite typical in an un-humidified commercial building in the winter, when the outside temperature falls below 10°C. Heating this cold air up to around 21°C, without adding any additional moisture, would easily take the air below the static threshold. If there is an additional source of heat from a machine or industrial process, then humidity will fall even lower.

The resulting static build-up can cause three effects. Surfaces can become attracted to each other, due to the electrical charges being opposite (opposites attract). Surfaces can be repulsed by each other. Or static build-up can discharge, causing sparks and the annoying jolts we feel when we do things like walk across a carpet and touch a metal doorhandle. In industries like printing, these effects can cause paper to jam on machines. In pharmaceutical manufacturing, it can mean pills don’t locate properly in blister packs. And in chemical manufacturing, an uncontrolled spark from ESD can literally cause an explosion.

"...voltages generated by activities such as walking across vinyl floors and synthetic carpets or getting up from a foam cushion can be reduced by between 92-98% at higher levels of humidity."

By proactively adding moisture to the air inside our buildings with a humidification system, the air’s humidity can be kept above this static threshold. Studies have shown that the voltages generated by activities such as walking across vinyl floors and synthetic carpets or getting up from a foam cushion can be reduced by between 92-98% at higher levels of humidity.

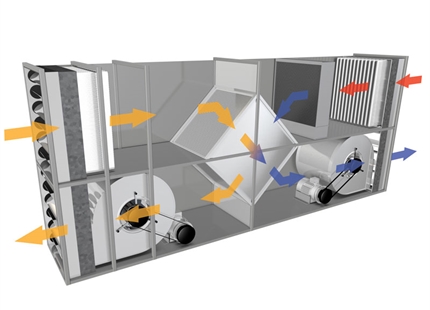

There are many industrial systems available to combat static, such as air ionisation systems, grounding wires or surface treatment systems. The benefit of humidifying a building to combat static is that it presents a comprehensive solution across a complete area. No matter how large or how small an area, there will be a commercial humidifier system capable of maintaining the ideal humidity. Cold water spray humidifiers can be used to manage the humidity across large production environments, whilst wall-mounted steam humidifiers can be a very convenient option for smaller rooms, such as digital printing rooms or MRI suites.

There are other benefits to maintaining indoor humidity at above 40%RH beside reducing static. A level of 40-60%RH is recommended by CIBSE in its Health & Wellbeing in Building Services (TM40:2020). At this humidity our respiratory immune system functions optimally, and the quantity and infectious nature of many airborne viruses is significantly reduced. These factors combine to reduce the impact of seasonal respiratory illness in the workplace and resulting sick days for a business. Additional productivity improvements are also enjoyed by manufacturers such as printers, packaging companies and food manufacturers, as moisture loss from materials and products is inhibited, with subsequent increases in product quality and reduced waste.